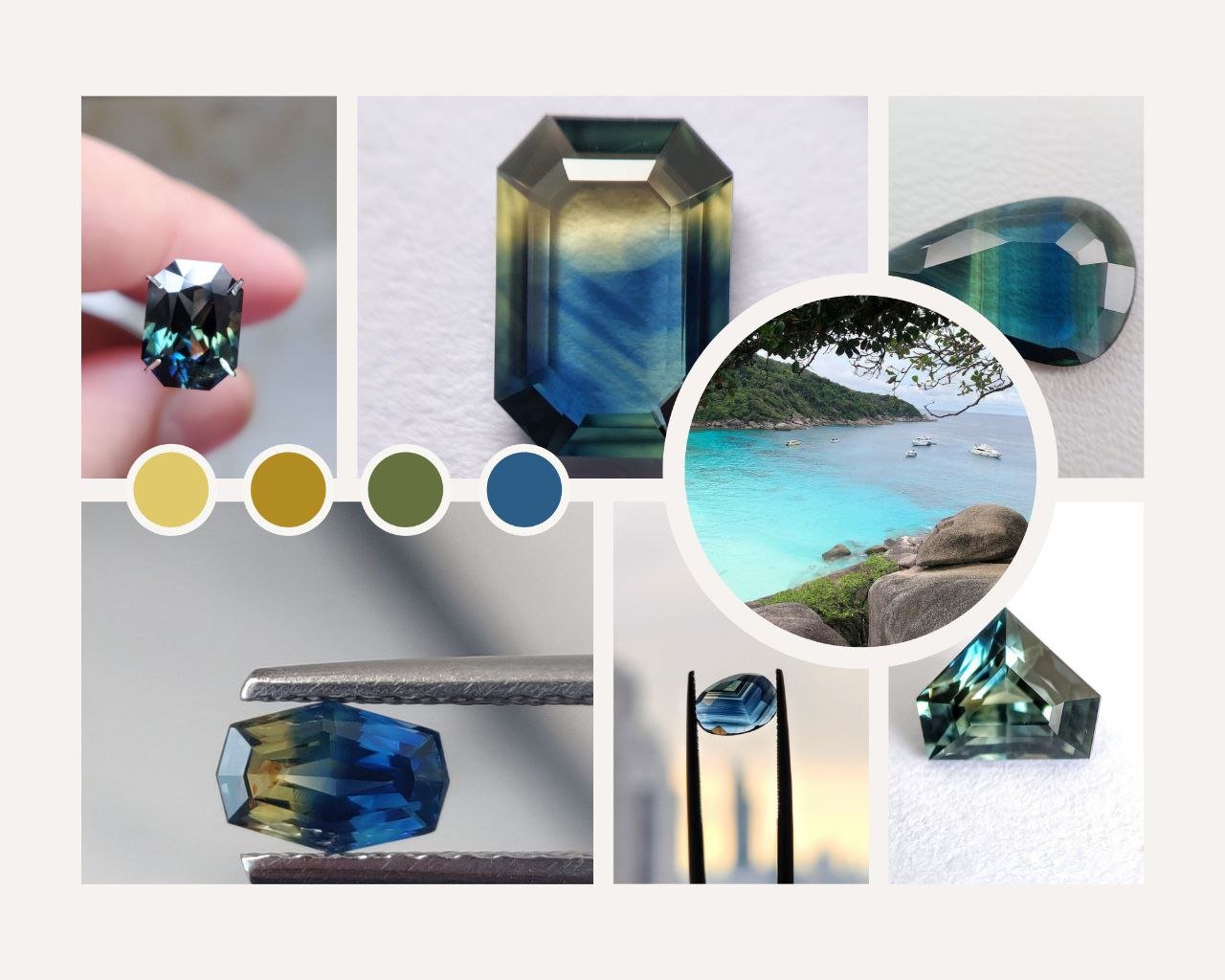

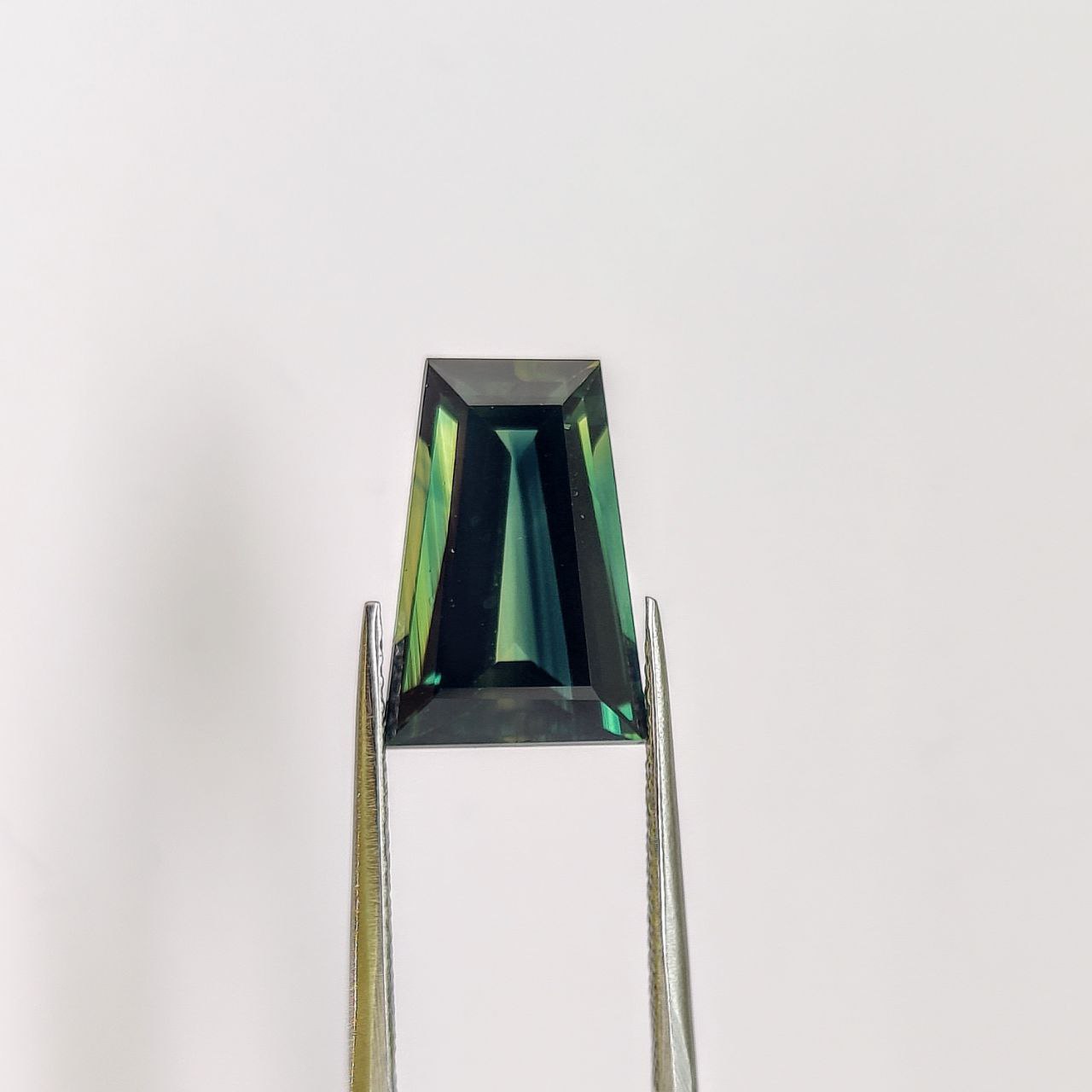

Range of Australian sapphires – Teal, mermaid, parti, bicolored sapphires

Today, pink diamonds from the Argyle mines have become synonymous with Australia as over 90% of the world’s pink diamonds are from this one mine. However, Australia has been mining other corundum, particularly sapphires and rubies, for over a century now and is one of the original natural blue sapphire production centers. As discussed in Part 1, Australia houses significant volumes in its minefields of Anakie, Queensland and New England district of New South Wales. With traditional sources like Kashmir having been exhausted many years ago, Australia contributes to over 70% of the global blue sapphire production today. However, it should be noted that jewelry houses of Europe as well as Asia today are excited about Australian parti sapphires, Australian teal sapphires and even Australian green and yellow sapphires over blue sapphires.

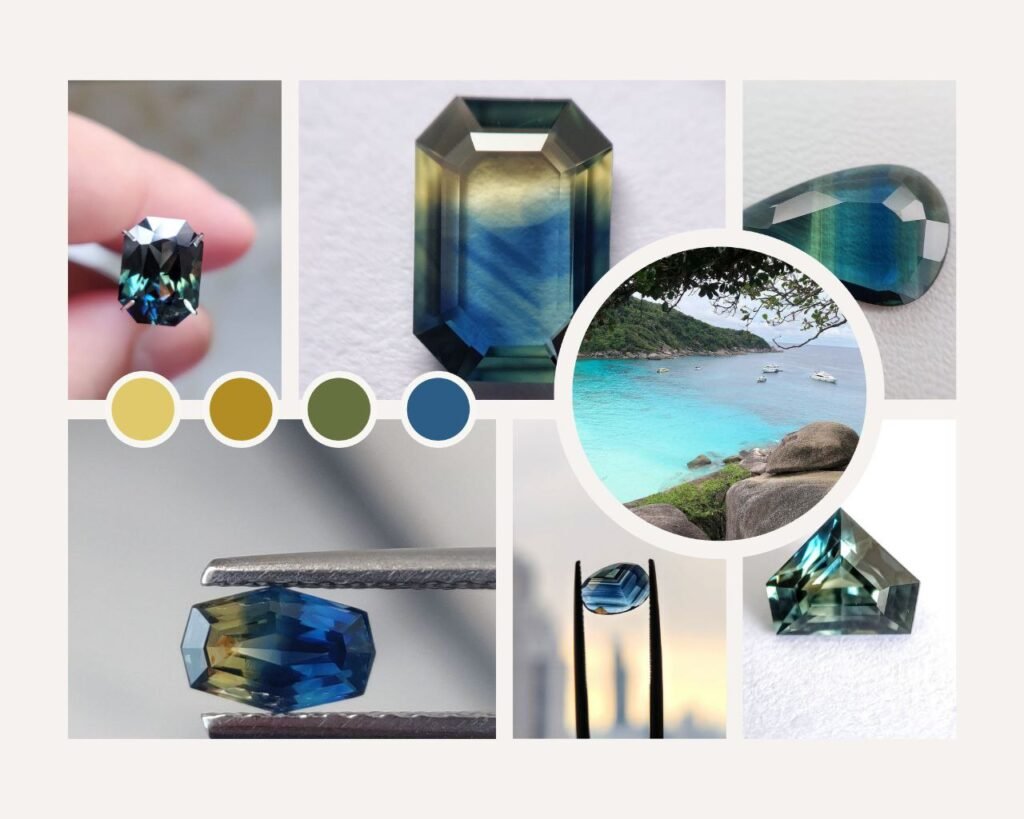

Now let’s inspect the image below carefully.

Can you tell which is the Australian sapphire of the two?

If you said “A”, you are right. Australian sapphires typically have a higher saturation, which makes them appear darker. The one on the right is a Ceylon sapphire or a Sri Lankan sapphire, that is more open and much less saturated. Therefore Australian sapphires have to be carefully cut so that the stone doesn’t appear dark and dull. This brings us to our next section:

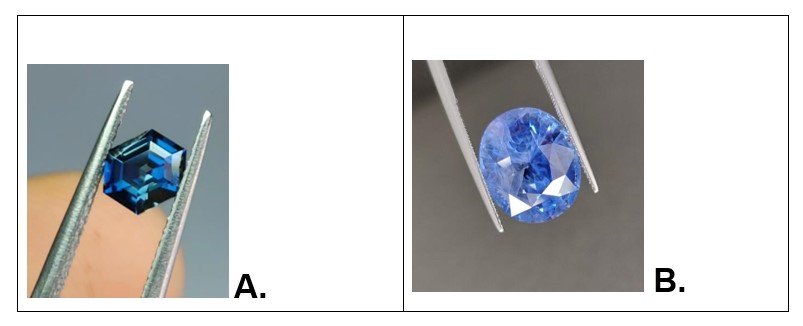

HOW ARE AUSTRALIAN SAPPHIRES CUT?

Cutting an Australian sapphire requires expertise. Unlike Ceylon sapphires and Montana sapphires that have an inherently open colour, lending themselves to a variety of cuts that showcase their internal fire, Australian sapphires must be cut carefully to not make them dark and opaque. Therefore, it should also be remembered that there is significant loss of weight in Australian sapphires. Let us see how it is done with respect to specific parts of a faceted gemstone:

Facets:

Facets can make or break investment grade sapphires. As a rule, the first facets in Australian sapphires are always bigger to avoid any darkness. Bigger facets always ensure more percentage of light return, which in turn makes the gem appear lighter and brighter.

Girdle:

The girdle for Australian sapphires needs to be perfect, just like diamonds. As these are inherently dark gems, the girdle should be kept thin to prevent the gems from appearing black.

Pavilion:

Due to the uniqueness of Australian sapphires, it is extremely essential to follow the correct guidelines while cutting these gems. Many gemologists recommend making the pavilion as close to that of diamonds as possible. The 4 Cs – cut, clarity, color and carat need to be kept in mind while cutting Australian sapphires. However, the color zoning present in certain Australian sapphires need special attention while making the pavilion. In some cases, the color zones are retained as it is while in others they need to be cut out to prevent the gems from appearing dark. For example, dark blue hues in a color zone turn black during faceting, and hence need to be deliberately removed from the final cut.

Shape:

Since Australian sapphires are dark, certain shapes are not suitable in the final cut. Round is the most preferred shape with these gems as this shape maximizes light return. Sometimes, it may be necessary to shed some weight on these gems and opt for a lean cut that enhances the look of the gems. Australian sapphires are the only sapphires that can be calibrated to a proper 9*7 oval.

Cutting an Australian Sapphire: What makes it special.

TREATMENTS FOR AUSTRALIAN SAPPHIRES

Like most sapphires, Australian sapphires are also subjected to heat treatment to improve their quality and clarity. It is mainly carried out in blue sapphires to enhance their colours and increase their transparency. Heat treatment generally depends on the number of silk deposits in these gems. The presence of silk affects the appearance of these stones negatively by imparting an “oily” nature and making them look dull. To overcome the dullness, the sapphires are heat treated to a temperature of 1400 ℃ or more to dissolve the silk and in turn enhance their beauty. Certain Australian sapphires may also be treated with Beryllium to adjust their colours to produce hues like intense orange, bright yellow or red.

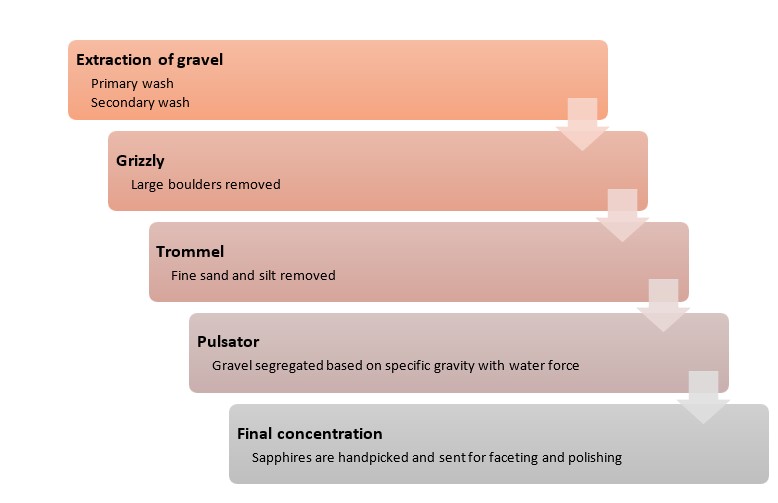

THE MINE TO MARKET PROCEDURE

Most Australian sapphires are thought to be of igneous or metamorphic origin. Through natural concentration processes, these gems accumulate in various layers of gravel known as wash. The wash layers can either be of primary (which refers to the original deposit in the waterways) or secondary (which are formed later by new streams that redistribute the older gravel) origin. The wash usually comprises an array of minerals like quartzite and silicates, apart from the sapphire gems. Hence, the extracted gravel is subjected to an elaborate filtering process to identify and sort out the gems. This is how the mining procedure is carried out:

The wash, which is concentrated with gravel, is shovelled with the aid of mining equipment, and transferred to a mining cart. Most of the machinery used is restricted to small and mobile handheld equipment to impart sustainability. The gravel is then loaded onto a bucket system that connects the underground mine to the wash plant present above the ground.

The collected gravel is further unloaded over a heavy set of bars known as “grizzly”. This is where the first separation process occurs, where all the heavy boulders are removed. The wash is then carried on a conveyor belt and fed into a trommel where the deposit is segregated and concentrated. The trommel has an outer mesh that gets rid of fine sand and silt. The conveyor belt is carefully controlled to ensure that only certain sized particles go through in the final concentration. Sometimes, sapphires that are under a certain size are also removed from the belt as they don’t have any commercial value.

The filtered deposit that accumulates at the end of the trommel is fed into a pulsator for the final concentration process. This is based on the specific gravity of the gems. Since sapphires have a higher specific gravity compared to other minerals like quartz, they can easily be separated. The pulsator beds consist of a series of ribs through which water continually flows through to pulse the gems up and down constantly. The water force is controlled to bounce out lighter materials like quartz and feldspar. Once the pulsing is completed, the machine is shut, and the collected deposits are inspected for gems.

The sapphires are usually trapped between the first few layers. They are handpicked from the wash and sent for faceting and polishing. It is interesting to note that only 20% of the mined sapphires are cut and faceted for jewellery making. The faceting and polishing of these gems are executed by experts who determine whether the gems need any further treatment. Some gems are heat treated to improve their clarity and appearance. Interestingly, a large amount of gems are transported to Thailand for the heat treatment as it is more economical.

WHAT MAKES AUSTRALIAN SAPPHIRES UNIQUE?

Unique appearance

Australian sapphires usually occur in darker tones compared to the other sapphires due to the higher iron content. Apart from the traditional blue colors, they also occur in plenty of bi-colored combinations. One such gem, that is extremely rare, is the ‘mermaid’ sapphire which is a combination of blue and green in 50:50 ratio. Parti sapphires are special Australian sapphires that present with distinct color zoning with the colors of blue, green and yellow.

In general, Australian sapphires are predominantly green with a bluish tint, and are thus often called bluish-green sapphires in the trade. This is one differentiating feature from Montana sapphires and other classical sources, which are predominantly blue with a hint of green, hence termed greenish-blue sapphires.

Sustainable sourcing

Australian sapphires are recovered from alluvial deposits without any chemicals or the production of toxic byproducts. In addition, the mining processes are carried out with small scale equipment which do not cause any heavy damage to the environment. This makes the excavation of these gems extremely low impact and sustainable in the long run. Apart from being environmentally friendly, the mining processes are also executed in an ethical manner, adhering to all necessary guidelines. Since these gems are responsibly sourced, they are gaining immense popularity amongst the younger, eco-conscious buyers.

Accurate labelling

Although more than half the Australian sapphires are heat treated, disclosure of the heat treatment process is standard practice. This may not be the case with gems that are sourced from other sources.

Affordable

Australian sapphires are available in larger sizes. This makes it possible for mass production, making the gems more affordable compared to their counterparts.

COMPETITORS OF AUSTRALIAN SAPPHIRES

Although Australian sapphires make up a majority of the world’s sapphire production, there are other equally good sources that produce fine gems. Some of them include Sri Lanka blue sapphires, Madagascar sapphires, Montana teal sapphires etc. Let’s look at how these differ from Australian sapphires:

| Sapphires | Colors | Characteristics | Heat Treatment | Mining practices |

| Ceylon | Vivid colors, lighter and brighter than other sapphiresCornflower Blue – most famousPink, yellow, green and rare orange-pink (Padparadscha) | Larger sizesYellow stones may be found in sizes of 5 carats | Heat treated to brighten the colorsMay also be treated with Beryllium | Most notable producers of fine sapphiresSmall scale mining with strict regulations |

| Montana | Pale green to blue green; more pastel huesyellow, orange,pinkrarely blue | High iron content High clarity | Minimal heat treatment | Quite uneconomical due to the small sizes of the gems |

| Madagascar | Variety of colors foundPink, yellow, green, white and orange (Padparadscha) | Almost indistinguishable from Ceylon sapphires | Heated at very low temperatures | No strict regulations yet |

| Australian | Variety of colors with darker tonesPopular – Deep BlueOther popular hues – teal, parti, blue-greenyellow, purple | Color banding may be seenHighly saturated | Presence of silk impedes the dispersion of colorIndustry-accepted heat treatment procedures are carried outLow heat treatments to increase transparency | Environmentally friendlySustainable mining with the use of limited machineryStrictly regulated practices |